Second Draft Review Conference of Blow-Fill-Seal Industry Technical Standards

On November 9, the "Second Draft Review Conference of Blow-Fill-Seal Industry Technical Standards" organized by China Pharmaceutical Equipment Engineering Association (CPAPE) and co-organized by SPM was successfully held in Shanghai. Main BFS technology users from all over the country, Representatives of pharmaceutical manufacturers and BFS experts and scholars attended this meeting.

In response to the requirements of epidemic prevention and control, this meeting was held in a combination of online and offline methods. Gu Weijun, executive vice president of CPAPE, Liu Weizhan, director of the Standards Department, and Bi Yong, chairman of the BFS Professional Committee, attended the meeting. Relevant experts from the General Regulations and Excipients and Packaging Materials Division of the National Pharmacopoeia Commission attended the meeting online. Experts and scholars from China Institute for Food and Drug Control, China Standardization Expert Committee, Shanghai Food and Drug Packaging Materials Testing Institute, as well as several main Pharmaceutical manufacetuers including Bausch & Lomb Pharmaceuticals, Otsuka Pharmaceuticals, Hubei Yuanda Tiantian Ming Pharmaceuticals, Xinhua Medical, Shandong Medical Pharmaceuticals,, Guangdong Lustre Pharmaceutical Co., Ltd., Nanjing Ruinian Best Pharmaceuticals, Jiangsu Cipla Pharmaceuticals, Chengdu Push Pharmaceuticals, Hebei Tiancheng Pharmaceuticals, Tianjin Jinyao Group, Shanghai Xinyi Jinzhu, Hebo Pharmaceuticals, Shandong Xinhua Pharmaceuticals, Chengdu Kang Hua Biological Products, Zhejiang Huahai Pharmaceutical, Guizhou Yibai, Weimo Biotechnology, Shuangfeng Gresheim Pharmaceutical, SPM, Rommelag Trading (Shanghai), Shanghai Tofflon, Rieckermann and other pharmaceuticals Relevant persons in charge of enterprises and equipment companies participated in technical seminars and manuscript review.

Mr. Gu introduced that the association's "Technical Requirements for the Production of Sterile Products Using BFS Process" will further promote the popularization process of BFS technology application and guide the development and application of related products and technologies. Through the last review meeting, there have been suggestions for drafting the standard, and we look forward to the results of the discussion on the second draft of the standard at this meeting.

At the meeting, Mr. Liu introduced in detail the standard formulation process, the purpose and content of the standard formulation, and emphasized the integrity and systemicity of the standard setting. After the establishment of the standard, the implementation stage requires the cooperation and support of various departments in the industry, including standard technical training and the in-depth participation of pharmaceutical companies.

Mr. Bi said that BFS technology has received more and more attention and recognition in China. This meeting will further improve the focus in BFS technical regulations, solve the puzzles encountered by pharmaceutical companies when applying BFS technology, optimize production processes, and improve the technological maturity of aseptic filling products.

Before the official start of the meeting, experts from the General Regulations and Excipients and Packaging Materials Division of the National Pharmacopoeia Commission expressed their high hopes for the association's development of group standards related to BFS technology. They believe that after the review meeting created the continuous progress and changes of current pharmaceutical companies and pharmaceutical equipment companies.

Ms. Bian, general manager of SPM briefly introduced the development history and technical advantages of BFS technology in China. Compared with the traditional aseptic filling of glass bottles, BFS technology has great aseptic effect. The visible impurity in the product is significantly lower. As a professional BFS equipment manufacturer, Shanghai VSUN Technology fully supports the popularization of the BFS technical group standard application and promotes members of the BFS industry to form a consensus in the development and application of BFS products and technologies.

Mr. Yang, a BFS technology application expert and deputy general manager of Shanghai VSUN Technology Co., Ltd., gave an in-depth explanation on the design of the BFS sterile preparation workshop, and analyzed the four basic technical support points of BFS technology aseptic protection, and the sterility assurance characteristics of BFS technology.

Mr. Li, chairman of Guangdong Lustre Pharmaceutical Co., Ltd., as the representative of the BFS study group of the CPAPE’s BFS group standard committee, briefly summarized the opinion solicitation situation of the first draft of the standard. Then he proposed that the discussion topic of the second draft was to unify participating companies' different recognitions of BFS technology and determine the common research direction. Mr. Li and his team members proposed amendments and explained each soliciting opinions in the summary form, The meeting discussed all the 33 opinions of the delegates on the first draft of the standard. The experts and scholars, representatives of the business community and relevant persons in charge of the association put forward their own opinions and adjustment suggestions on each point. Everyone conducted a lively discussion on different viewpoints.. The association collects the opinions of the participants on the revision of the second draft, and prepares for the formulation of the perfect standard.

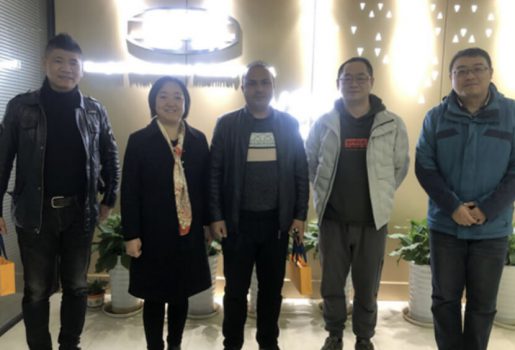

During the conference, the participating experts and representatives visited SPM the conference organizer and the professional BFS aseptic plastic packaging blow-filling and sealing system manufacturer. The participants visit BFS equipment workshop and focused on understanding the company’s development history, equipment development and market applications.