SPM Capsule Filling Machine: Key Equipment In The Modern Pharmaceutical Industry

With the continuous advancement of science and technology, the pharmaceutical industry is also developing rapidly. As a key equipment in the modern pharmaceutical industry, capsule filling machines play an important role in the pharmaceutical production process.

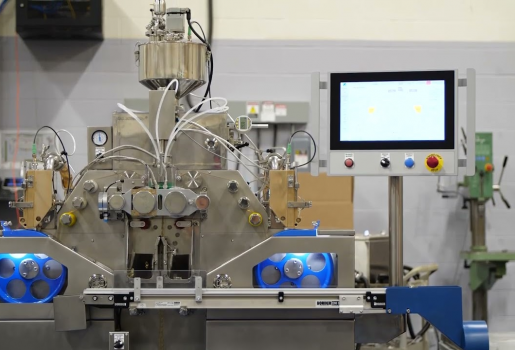

1.Principle of Capsule Filling Machine

Capsule filling machine is an automated equipment mainly used to fill drug powder or granules into empty capsules. Its working principle is to use mechanical arms and conveyor belts to grab empty capsules one by one, fill the capsules with drugs through a precise metering system, and then send them out through the conveyor belt to complete the entire filling process.

2.Structure of Capsule Filling Machine

The capsule filling machine mainly consists of the following parts:

Robotic arm: used to grab empty capsules and place them in the filling position.

Conveyor belt: used to transport empty capsules and filled capsules to designated locations.

Metering system: Used to precisely control the amount of drug filling to ensure a consistent amount of drug in each capsule.

Control system: used to control the entire filling process to ensure the normal operation of the equipment.

3.Application of Capsule Filling Machine

Capsule filling machines are widely used in the pharmaceutical production process, mainly in the following aspects:

Improve production efficiency: The capsule filling machine adopts automation technology and can quickly and accurately fill drugs into empty capsules, greatly improving production efficiency.

Guaranteed product quality: Through a precise metering system, the amount of medicine in each capsule can be ensured to be consistent, thereby ensuring product quality.

Reduce labor intensity: The capsule filling machine can reduce the labor intensity of manually filling capsules and improve production efficiency.

Strong adaptability: The capsule filling machine can adapt to the filling needs of empty capsules and drug powders or granules of different specifications and types.

4.Development Trend of Capsule Filling Machine

With the continuous advancement of science and technology and the development of the pharmaceutical industry, capsule filling machines are also constantly developing and improving. In the future, capsule filling machines will develop in the following directions:

Intelligent: With the continuous development of artificial intelligence and machine learning technology, capsule filling machines will be more intelligent in the future, able to automatically identify and handle various abnormal situations, improving the operational stability and production efficiency of the equipment.

Efficiency: In order to meet the growing market demand, capsule filling machines will further improve production efficiency, shorten the production cycle, and reduce production costs in the future.

Green and environmentally friendly: With the continuous improvement of environmental awareness, capsule filling machines will pay more attention to environmentally friendly design in the future, using environmentally friendly materials and processes to reduce the impact on the environment.

Multifunctionality: In order to meet the needs of different users, capsule filling machines will have more functions in the future, such as filling multiple drugs at the same time, automatic sorting and packaging, etc.

Modular design: In order to facilitate the maintenance and upgrade of the equipment, the capsule filling machine will adopt a modular design in the future, and each module can be easily replaced and upgraded.

In short, with the continuous advancement of science and technology and the development of the pharmaceutical industry, capsule filling machines will play a more important role in the future. We believe that in the near future, capsule filling machines will be more intelligent, efficient, green, multi-functional and modular in design, making greater contributions to the development of the pharmaceutical industry.