Product

BFS Plastic Ampoule Production Line are highly used in eye, ear, nose care products and cosmetic serums. Comparing to glass ampoule, plastic material has much more advantages such as convenient to use, eliminate potential hazards in handling, safe and environmentally friendly disposal, shatterproof transportation and low manufacturing cost.

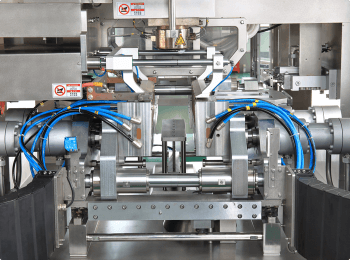

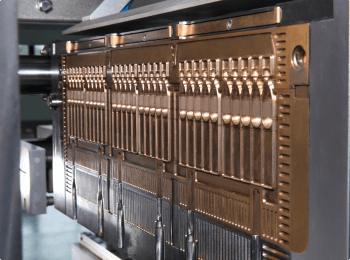

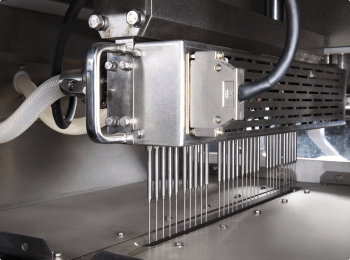

AFP aseptic blow fill seal system for plastic container parenterals double station uses two sets of molds and cutting system. This structure use the extruder waiting interval during mold forming and filling process to work on an additional set of mould extrusion. VSUN double station model has a much higher production capacity and connect conveyer belt from both sides of the machine. Various capping design such as twist off, multidose, euro cap and more can be chose upon request.est.

| Model | Specification | Nos.of Extruding Head | Center Distance of Extruding Head | Qty. of Mould | Distribution of Cavity | Total number of cavity | Recycle Time (Unit:s) | Production Capacity (Unit:pcs/h) |

|---|---|---|---|---|---|---|---|---|

| AFP3D | 0.4-2mL | 3 | 145 | 2 | 2×3×(5+5) | 60 | 14 | 15000 |

| AFP3D | 5-20mL | 3 | 145 | 2 | 2×3×6 | 36 | 14 | 9000 |

| AFP4D | 0.4-2mL | 4 | 110 | 2 | 2×4×8 | 64 | 14 | 16000 |

| AFP4D | 5-20mL | 4 | 110 | 2 | 2×4×5 | 40 | 14 | 10000 |

Our professional team will reply to you as soon as possible.

Tel

+86-21-33522115 / 33522116

WhatsApp/Skype/WeChat