Product

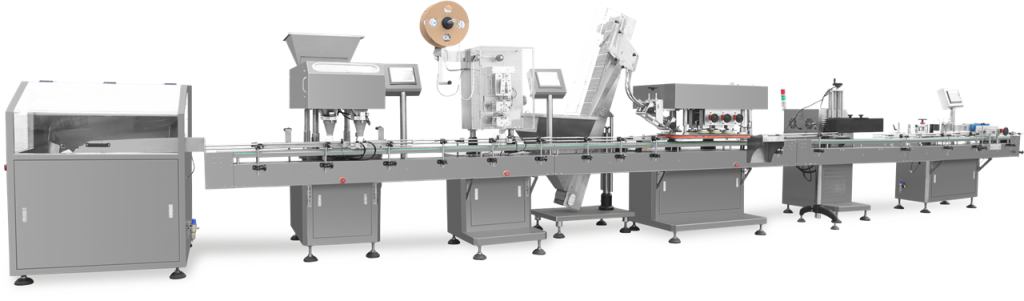

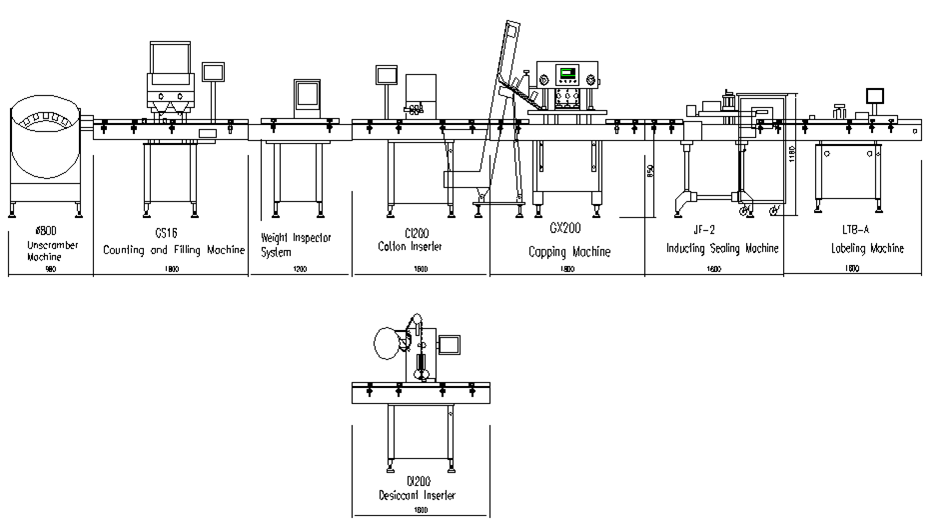

Fully automatic tablet capsule candy gum counting packaging line that can count hard capsules, soft capsules, tablets,pill, snack foods, hardware,gum etc., it has a wide range of applications. The whole line consists of a bottle unscrambler, an electronic counting machine, a desiccant insertion machine, aluminum foil sealing machine, a capping machine, and a labeling machine. All machines can be operated synchronously after connection and ensure stability. Each machine of this production line can adjust quickly and use independently. And the whole production line can assemble and separate easily and quickly. The outer frame of the machine is made of 304 stainless steel, and the contact part is made of 316 stainless steel.

SLP200 sorts round, rectangular and square bottles automatically and places the containers on a conveyor at speeds up to 100 cpm. This unscrambler adopts electronic timing system. The operation is easy and stable. It is useful widely in the pharmacy, food & beverage, cosmetic & personal care industries.

Specifications:

| Sorting Speed | 40-100 bottles/minute |

| Bottle size | customized based on the requirements |

| Dimensions | 1000mm×1100mm×1300 mm ( Length × Width × Height ) |

| Weight | 280kg |

| Electrical Requirements | — Power: 500W, Voltage: 220v, Frequency: 50-60HZ(Optional) |

| Working direction | Left → Right (or Right → Left) |

Industry Type(s)

Features:

Stainless steel frames and cabinets

This high-speed tablet and capsule counter combines 16-channel counting heads over a dual-track conveyor on a single frame to double the throughput without doubling the floor space, achieving speeds up to 60 cpm based on 100-count bottles. The machine handles a wide variety of tablets, caplets and both hard and soft capsules of different shapes, sizes and properties.

Features

Specifications:

| Counting & Filling Speed | 3000-6000 pieces/minutes based on 20-999 pieces/bottle ( customized based on the requirement ) |

| Bottleneck size | ≥Φ25 mm ( customized based on the requirements ) |

| Bottle size | Φ35 mm – 60 mm ( customized based on the requirements ) |

| Dimensions | 1800mm×1420mm×1600 mm ( Length × Width × Height ) |

| Weight | 280kg |

| Electrical Requirements | — Power:500W, Voltage: 220v, Frequency: 50-60HZ(Optional) |

| Working direction | Left → Right (or Right → Left) |

Industry Type(s)

DI200 is economical and easy to operate. The machine can automatically cut off the belted desiccant and insert it into the container accurately and speedy. This fully automatic machine inserts a predetermined length of desiccant coil into containers at speeds up to 80 cpm.

Features:

Specifications:

| Insert Speed | 40-80 bottles/minutes |

| Dimensions | 1600mm×600mm×1500 mm ( Length × Width × Height ) |

| Weight | 250kg |

| Electrical Requirements | — Power: 1500W, Voltage: 220v, Frequency: 50-60HZ (Optional) |

| Working direction | Left → Right (or Right → Left) |

Industry Type(s)

GX200 is economical, and easy to operate. This versatile in-line capper handles a wide range of containers at speeds up to 200 bpm and offers a quick and easy changeover that maximizes production flexibility. The tightening discs are gentle which will not damage caps but with a excellent capping performance.

Features:

Specifications:

| capping Speed | 50-200 bottles/minutes |

| Bottles size | Φ30~120 mm, height (can be customized based on the requirements) Dimensions: 1800mm×850mm×1850 mm ( Length × Width × Height ) |

| Weight | 450kg |

| Electrical Requirements | — Power:1000W, Voltage: 220v, Frequency: 50-60HZ (optional) |

Industry Type(s):

JF-2 is new generation production which adopts electromagnetic induction technical. The machine is economical and easy to operate. It uses widely in food& beverage, Pharmaceuticals and chemical industry etc. This fully automatic sealing machine can seal the mouth of container with aluminum foil at speeds up to 120 cpm.

Features:

Specifications:

| Sealing Speed | 50-120cpm ( based on the diameter of bottleneck) |

| Diameter of bottleneck | Φ20-80mm |

| Dimensions | 1600mm×600mm×1300 mm ( Length × Width × Height ) |

| Electrical Requirements | — Power: 2000w, Voltage: 220v, Frequency: 50-60HZ (Optional) |

| Working direction | Left → Right (or Right → Left) |

Industry Type(s)

LTB-A is economical, self contained, easy to operate, equipped with LCD screen & PLC Control System. Built in microchip storing different job setting makes fast and easy changeover. This automatic labeling system is ideal for cylindrical container with diameter from 30mm – 100mm.

Features:

Specifications

| Labeling Speed | 80-200 bottles/minutes (according to the specification, shape of bottle and length of label) |

| Bottles size | Φ30~100 mm, height (can be customized based on the requirements) |

| Dimensions | 1600mm×700mm×1100 mm ( Length × Width × Height ) |

| Weight | 200kg |

| Electrical Requirements | — Power:300W, Voltage: 220v, Frequency: 50-60HZ(Optional) |

| Working direction | Left → Right (or Right → Left) |

Industry Type(s)

Our professional team will reply to you as soon as possible.

Tel

+86-21-33522115 / 33522116

WhatsApp/Skype/WeChat