Product

Series of BGB High-effect coating Machine is special equipment on coating for Chinese and Western tablet, pill etc, coating for thin film of aqueous phase and organic matter, and adopted the materials of high-quality & stainless steel to make. In the processing of operation can be controlled by computer programmable system and manual operation, touch screen display the picture. It is sound in beautiful appearance, advance & all round functions, high-efficiency saving for energy, simply operation, convenient clearing etc. and is the ideal coating equipments.

| Type | BGB-10 | BGB-40 | BGB-80 | BGB-100 | BGB-150 | |||

| Production capacity | 10kg/time | 40kg/time | 80kg/time | 100kg /time | 150kg /time | |||

| Diameter of coating drum | ф500mm | ф760mm | ф940mm | ф1050mm | ф1200mm | |||

| Diameter of feeding moth | ф300mm | ф340mm | ф380mm | ф420mm | ф480mm | |||

| Rotating speed of coating drum | 2~20r/min | |||||||

| Electrical motor power of main body | 0.55kw | 1.1kw | 1.5kw | 2.2kw | 2.2kw | |||

| Electric motor power of air heater | 0.37kw | 0.75kw | 1.1kw | 1.5kw | 1.5kw | |||

| Electrical motor power of exhauster | 0.75kw | 2.2kw | 3kw | 5.5kw | 5.5kw | |||

| Air heater flow | 816m3/h | 1283m3/h | 1685m3/h | 2356m3/h | 2356m3/h | |||

| Exhauster flow | 1285m3/h | 3517m3/h | 5268m3/h | 7419m3/h | 7419m3/h | |||

| Main body noise | ≯75db(A) | |||||||

| Air heater noise | ≯75db(A) | |||||||

| Exhauster noise | ≯75db(A) | |||||||

| Appearance size of main body | 900X700X1400 | 1100X850X1470 | 1370X1050X1700 | 1450X1150X1900 | 1570X1260X2030 | |||

| Main body weight | 200kg | 500kg | 600kg | 850kg | 850kg | |||

| Appearance size of exhauster | 750X600X1130 | 820X720X1750 | 900X820X1650 | 1000X900X1650 | 1000X900X1650 | |||

| Exhauster weight | 300kg | 450kg | 500kg | 550kg | 550kg | |||

| External Condition | Heating type with Vapor | Power supply | Three- phase four- wire 3kw | Three- phase four- wire 6kw | Three- phase four- wire 9.5kw | Three- phase four- wire 12kw | Three- phase four- wire 13kw | |

| Purify air | Pressure | ≥0.4Mpa | ||||||

| Air consumption | 0.2m3/min | 0.5m3/min | 0.35m3/min | 0.45m3/min | 0.5m3/min | |||

| Vapor | Pressure | ≥0.4Mpa | ||||||

| Air consumption | 30kg/h | 60kg/h | 80kg/h | 100kg/h | 100kg/h | |||

| Water head | Pressure | ≥0.15Mpa | ||||||

| Cabliber | 1" | |||||||

| Power supply | Three-phase four-wire 10kw | Three-phase four-wire 16kw | Three-phase four-wire 20kw | Three-phase four-wire 25kw | Three-phase four-wire 25kw | |||

| Purify air | Pressure | ≥0.4Mpa | ||||||

| Air consumption | 0.2m3/min | 0.2m3/min | 0.35m3/min | 0.5m3/min | 0.5m3/min | |||

| Water head | Pressure | ≥0.15Mpa | ||||||

| Cabliber | 1" | |||||||

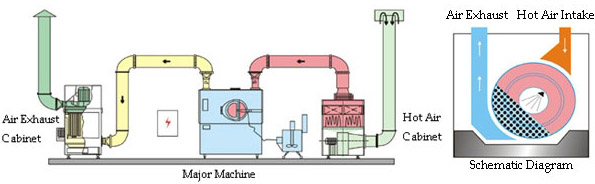

Coating Technical Process Flow

Air Exhaust Cabinet: Used for pumping air out of drum in the major machine(including dust absorption),keeping the working area under negative pressure.Equipped with a vibration damper. The exhaust outlet is equipped with a reflux-prood device.Close the exhaust cutlet before stop the machine to prevent the air in the exhaust cabinet from reflux. It is equipped with a dust abatement and filtration by vibration. So the vibration and dust are insulated, the dust is presented from fly off and the dust abatement is automatically separated, which makes cleaning easy.

Hot Air Cabinet: Firstly,aire inhaled in through the centrifugal fan should be purified up to the 100,000 Level after three times filtration, involving primary filtration, medium filtration and high filtration, then be blown to the drum of main machne through more in accordance with GMP.

Our professional team will reply to you as soon as possible.

Tel

+86-21-33522115 / 33522116

WhatsApp/Skype/WeChat