Product

Model RG2-110 soft-capsule production line is a new generation of rolling-mold water-cooled soft-capsule line optimally designed and finely manufactured on the basis of foreign latest technology.

Its main technical specifications reach the international advanced level and conform to standard GMP.

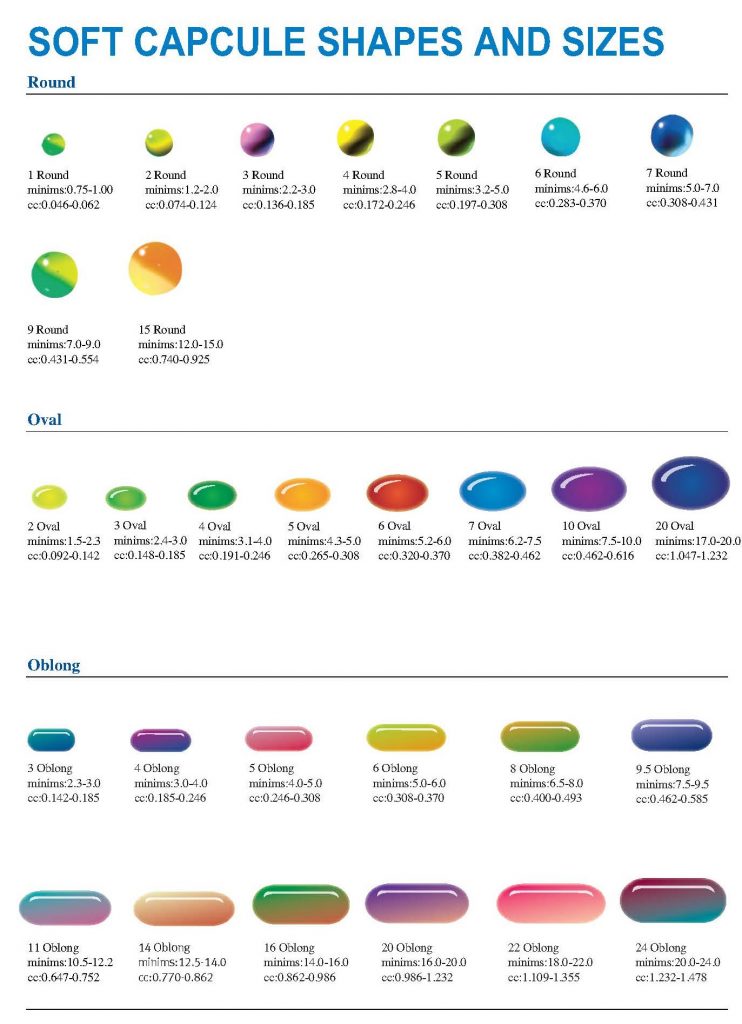

Model RG2-110 soft-capsule production line consists of the gelatin-melting pot, thermal-insulated gelatin-storage pot, electrical control panel, main machine conveyor, setting-drying rotary-cage, ruptured-gel recovery unit, and colloid mill. It works under the following principles. The oily or gelatin-insoluble liquids, pastes, or plasters (e.g. extract form Chinese Medicine Herbs) are injected into between two rolling gelatin skins in a given quantity, cut, and then formed through two rolling molds into various-shaped soft-capsules, such as egg-shape, fish-shape, cylindrical shape ball-shape and calabash. These products are widely used in many industries such as medicine, cosmetics, health goods and pesticides.

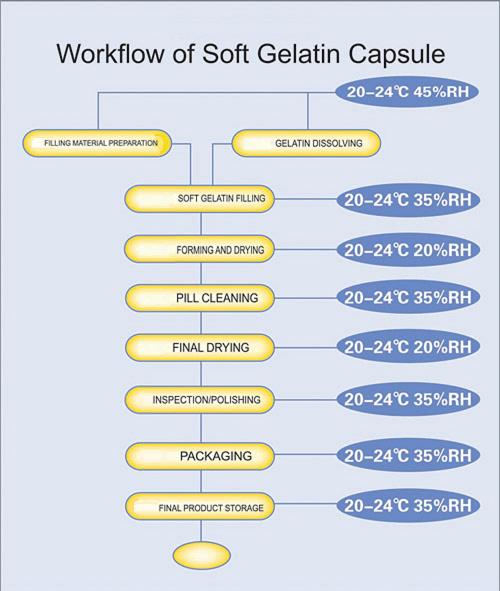

Workflow Of Soft Gelatin Capsule

| Model | RG0.8- I10 |

|---|---|

| Die Roller Speed | 0-3.5r/min |

| Die Roller Dimension | ¢72 x 110 |

| Single Piston Pump Material Supplied | 0-0.8ml |

| Power Supply | 380V 50Hz 0.75Kw 220V 0.75Kw |

| Noise target | <70dBA |

| Overall Dimensions | 850 x 750 x 1520mm |

| Net Weight of machine | 400kg |

Conveyor

For convenient operation, it is directly fixed on the main machine. The food grade conveyance belt of Lexno Corporation (USA) (FDA approved) is non-toxic, non-sticky, and easily washable, and it eliminates both the difficulties in thorough clearing of the gaps between the meshed stainless steel belts and the cross-contamination in production of different varieties.

| Working Length | 750mm |

| Liner Velocity | 2.5m/min |

| Power Supply | 220V 25W |

| Overall Dimensions | 950 x 260 x 200 |

Electrical Control Panel

The electrical control panel of the main machine is used for control of running and thermostat of the main machine, the conveyor, the thermal-insulated gelatin-storage pot, and the setting-drying rotary-cage, as well as for frequency-conversion infinite speed-adjustment and digital display and in order to ensure high reliability and service life in the panel elements from international famous manufacturers are used.

Thermal-insulated Gelatin-storage Pot

| Volume | 170L |

| Water Stored Quantity | 60L |

| Heater Power | 220V 2Kw |

| Temp. Control Range | 0℃-99℃ |

It is used to store the gelatin solution during production of the soft capsules.

Setting And Drying Cage

| Shaping Rotator Joint Quantity | 4 |

| Shaping Rotator speed | 8r/min |

| Power supply | 380V 370W X 4 |

| Fan capacity | 2500m3/h x 2 |

| Fan power | 380V 320W X 2 |

| Overall Dimensions | 3900 x 610 x 1100mm |

| Net Weight of machine | 400Kg |

Each group of setting-drying cage consists of 4 sections and both end faces are providing with fans. The driving system of each section may be clockwise and counterclockwise rotated and independently controlled. It is mainly used for setting the capsules soft capsules formed from the main machine and for drying of the cleaned capsules.

Our professional team will reply to you as soon as possible.

Tel

+86-21-33522115 / 33522116

WhatsApp/Skype/WeChat